Does stainless steel wire mesh rust easily?

As a stainless steel wire mesh supplier, I have some information to share with you. When the surface of the stainless steel tube appears brown rust spot (point), people marvel: "stainless steel is not rusty, rust is not stainless steel, may be the steel has a problem." In fact, this is the lack of understanding of stainless steel one-sided misunderstanding. Stainless steel wire mesh will rust under certain conditions.

Stainless steel has the ability to resist atmospheric oxidation-namely rust, but also has the ability to resist acid, alkali, salt corrosion-namely corrosion resistance. However, the corrosion resistance varies with the chemical composition of steel itself, the state of interaction, service conditions and types of environmental media. For example, 304 steel pipe in the dry clean atmosphere has absolutely excellent rust performance, but moved to the coastal area, in the sea fog containing a lot of salt will rust quickly; And 316 steel pipe will perform. good Therefore, it is not any kind of stainless steel, it is resistant to corrosion and rust in any environment.

Fine stainless steel wire mesh is a layer of very thin, stable, fine-grained material, constantly entering and constantly oxidizing, to achieve the ability to rust. Every now and then, for whatever reason, the membrane breaks down, air or liquid gets in, or the iron atoms in the metal separate, forming loose oxygen and rusting. Therefore, stainless steel wire mesh will not rust forever, as long as we do the right cleaning and maintenance work for a long time, to increase the life of the product, greatly reduce the damage rate, and then reduce the cost of product replacement is beneficial.

Stainless steel is formed on the surface of the very thin and strong and stable chromium rich oxide film (protective film), to prevent oxygen atoms continue to penetrate and continue to oxidize, so as to obtain rust resistance. Once for some reason, the film continues to be destroyed, oxygen atoms in the air or liquid continue to infiltrate or iron atoms in the metal continue to separate, forming loose iron oxide, the metal surface continues to rust. This kind of surface film is destroyed in many forms, common in daily life are the following:

1.stainless steel wire mesh surface contains dust or other metal particles attached to other metal elements. In humid air, condensed water between the attachment and the stainless steel connects the two into a miniature battery that generates electricity. In a chemical reaction, the protective film is destroyed, known as electrochemical corrosion.

2.stainless steel surface attached organic juice (such as wax gourd, noodle soup, glutinous rice, etc.), water and oxygen form organic acids, organic acids corrosion metal surface for a long time.

3.stainless steel surface attached acid, alkali, salt substances (such as alkali water, stone water splashed on the wall), resulting in local corrosion.

4.in the polluted air (such as containing a lot of sulfide, carbon oxide, nitrogen oxide atmosphere), in case of condensed water, sulfuric acid, nitric acid, the formation of acetic acid liquid point, causing chemical corrosion.

Other stainless steel wire mesh companies recommend the following:

1.Anping county Tengde metal wire mesh products co.,ltd.is a manufacturer with 20 years experience on productions and research and development. main products include stainless steel wire mesh, wire mesh production series ,filter and filter material.more information click here.

2.Anping Beginning Wire Mesh Co., Ltd. is a direct manufacturer and exporter of wire mesh and woven wire cloth. We have more than 20 years experience in wire mesh industry, so we have our own raw material factory, advanced weaving machines & experienced technicians, strict inspection process and etc.

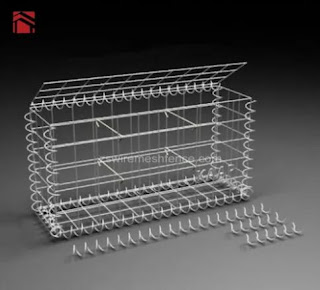

3.Raoyang Zerun Metal Wire Mesh Co.,Ltd is one professional producer of Welded Mesh Fence,358 Security Fence,Palisade Fencing, Razor Wires, Military Defensive Barrier, Gabion,Gate with mesh. Contact us for more information.

评论

发表评论